Efficiency

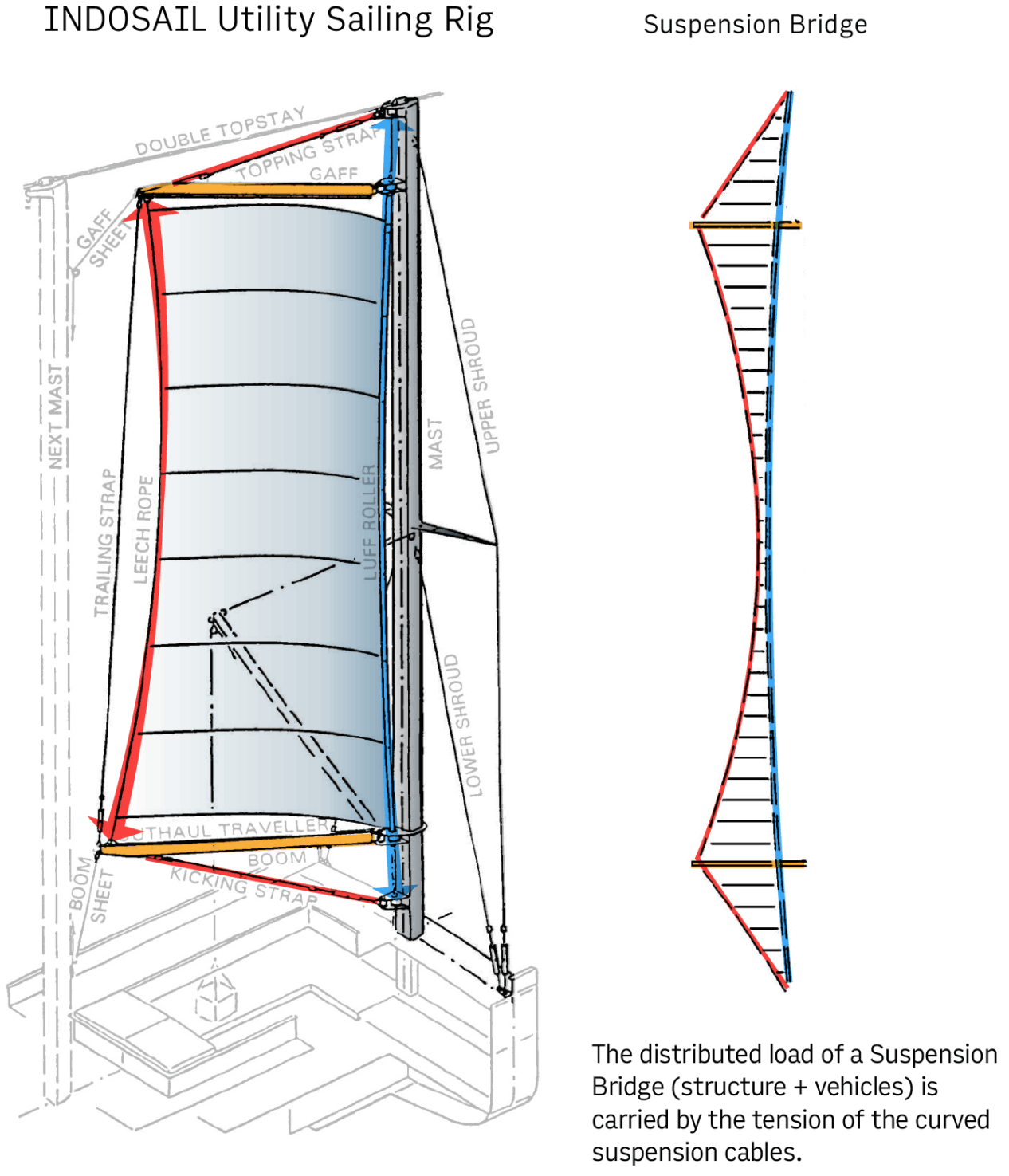

All sails are made of soft UV-resistant cloth. They are of flat

cut with a hollow curved leech seam. The sails under wind load

are suspended by a strong, curved leech rope similar to a

'suspension bridge'.

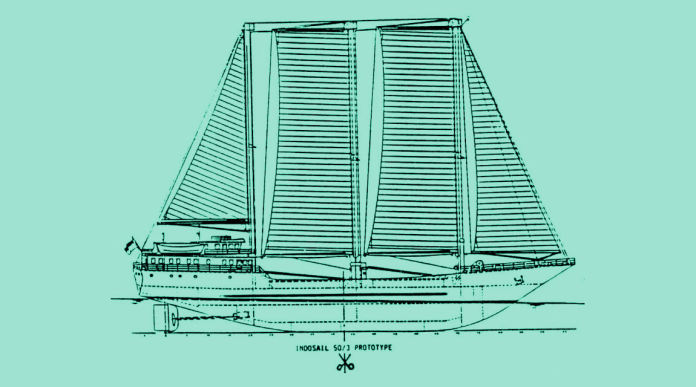

In a multi mast sailing rig—as with an aircraft wing in the start or landing configuration—the optimum adjustment of the sail- or wing elements to the local

flow conditions is resulting in a fairly open sheeting of the jib

and a progressively closer sheeting of the following sails, with

the mizzen sheeted closest. The purpose is to force the wind flow—step by step—to turn its direction closer to the midship line, for

optimum propulsion thrust and even distribution of the

contributions of the sail elements.

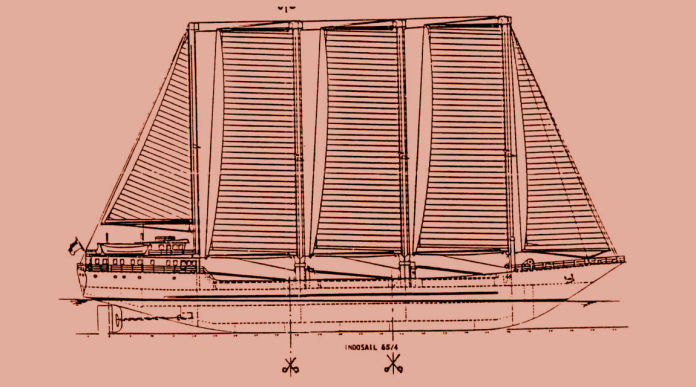

A fore-and-aft mainsail attached to the mast or a luff roller

close to the mast is suffering from disturbed flow on its most

critical leading edge. The gap between mast and roller is

marginally improving the flow but a considerable improvement is

found from the slipstream of a jib sail in front. Thus the

propulsive effect of the combination is much more than the sum

of the effects of the individual sails.

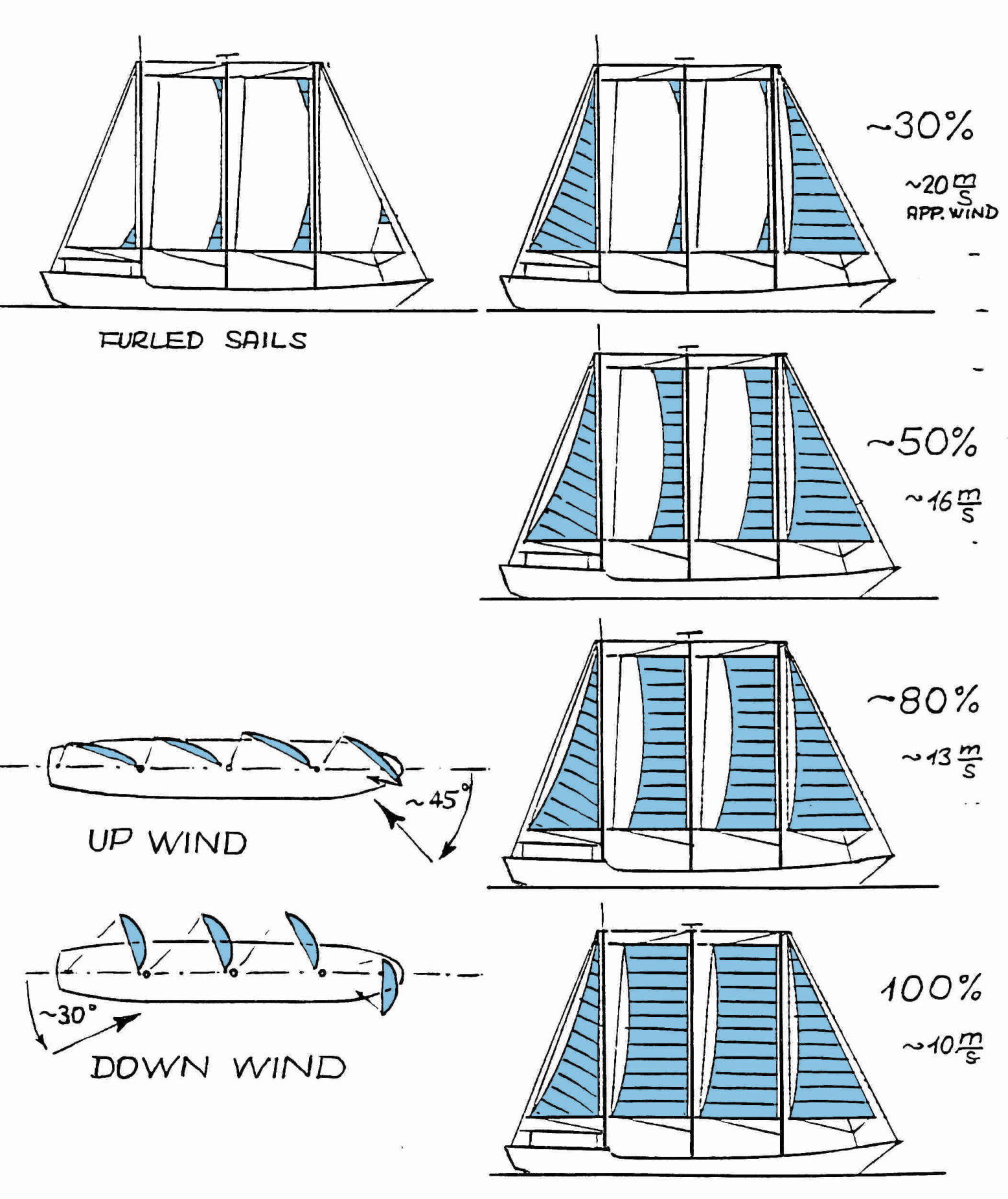

Consequently, to open the gaff sails only is not an efficient

configuration. It is suggested instead, to open the jib and

mizzen sails first and to open the gaff fore and mainsails then

to a degree compatible with the course and wind conditions.

With increasing wind speeds, the gaff sails should be reefed

progressively with the jib and mizzen sails still full.